- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

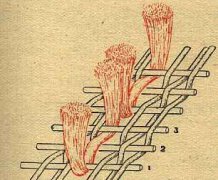

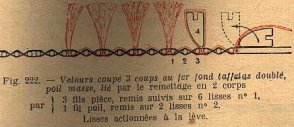

The warp is organsine 2 and 3 ends 20/22. The weft, coarse, is a doubling of silk, irregular thread resulting from unwinding of the double cocoons. Weaving with a plane with 4 irons 1 bottom roll, 1 roll of pile

We can notice that the use of this douppion weft is contradictory with the velvet. It was necessary to hit the beating very hard twice in a row to "try" to bring in the reduction. This contradiction led to a fabric of a very particular aspect on which opinions were very divided. We have woven hundreds of meters of this velvet in various colors and have never managed to get used to the douppion beads coming to massacre the velvet squares. However, it seems that this fabric has had some success since it was made over several decades.

In order to cut the pile threads which pass over the groove of the iron, a tool called a planer is used and in which a piece of Gillette blade is set so that it does not scrape at the bottom of the groove of the iron, Inevitably its rapid wear (cutting the iron). The groove thus serves as a guide for the blade which slots the loops into tufts of hair.

This diagram illustrates well the two frames framing the tufts of hair: they have the same crop to tighten the tuft to the maximum.

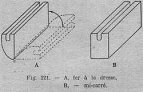

There are two types of irons: the flat irons that slip flat, the tainure of the side of the comb and straighten up at the thrust. And the square (or half-square) irons that slip into the definitive position, ie groove turned upwards. The irons at the top mark less the velvet and are therefore used in velvets with great reduction.

The doubling of the crossings on the 2 strokes of frame which surround the iron results in a change in the height of the ratio of the weave used.

Silk velvet, cut in irons, is only woven into looms. The irons used are of brass, with a length greater than the width of the fabric on the loom. The groove made over its entire length on its upper face serves as a guide to the blade which cuts the loops of the pile thread into velvet tufts.

Here are two planes, tools used to cut the velvet loops on the iron to get the tufts of the cut velvet.

Plain velvet cut with irons.

There is the cut pile made of pile and the curly pile, made of loops; there is the plain pile and the shaped pile; there is the chiseled pile which combines curly and cut pile pile.

Weaving of checkered velvet at the Atelier du Chelu in 1981

Description

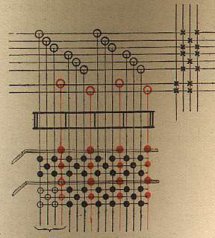

The velvet cut with the irons are obtained by means of two warps, distributed in the traditional proportions of 2 threads piece for 1 hairy thread or 3 threads piece for 1 hairy thread. They are woven with irons that have a groove in any length and that are inserted between the hair yarns and the piece yarns. When the pile yarns are firmly bound by their crossing with the weft, the first iron is cleared by severing the wrapping yarns by means of a steel blade slid along the groove. The filaments which make up these threads disintegrate by cutting and form small tufts of velvet tightened one against the other.

The bottom of the velvet cut to the irons is obtained by means of 2 warps distributed in the traditional proportions of 2 threads piece for 1 wire hair or 3 threads pieces for 1 wire hair. They are woven by means of irons which have a groove in their entire length and which are inserted between the hair wires and the workpiece wires.

When the pile yarns are firmly bound by their crossing with the weft, the first iron is cleared by severing the pile threads which envelop it by means of a blade slid into the groove of the iron, forming small tufts of velvet tightened one against others.

The bottom of the plain cut velvet is generally taffeta or the twill of 3 lie 1. It is a matter of fixing the tufts of velvet firmly to the bottom fabric.

The rules to follow are:

- The pile threads cross as much as possible against the irons

- The piece wires are armored in such a way that there is no change of crook on the two blows between which the irons are placed, the same play of the wires repeating on these two blows.

- The tufts of hair are thus enclosed by two frames strongly pressed against each other because they have my same crook, as shown in the figure below.

- The lateral displacement of the pile tufts, due to their sliding on the weft, is avoided by opposing the play of the piece threads to that of the pile threads.